Lubrication is precisely applied to each drivetrain by robots during assembly, and drivetrains are thoroughly analysed using an accelerated wear test to ensure your Hemera will have many years of 3D printing life. Each Hemera drivetrain includes shielded bearings and high quality igus® bushings for optimal wear resistance.

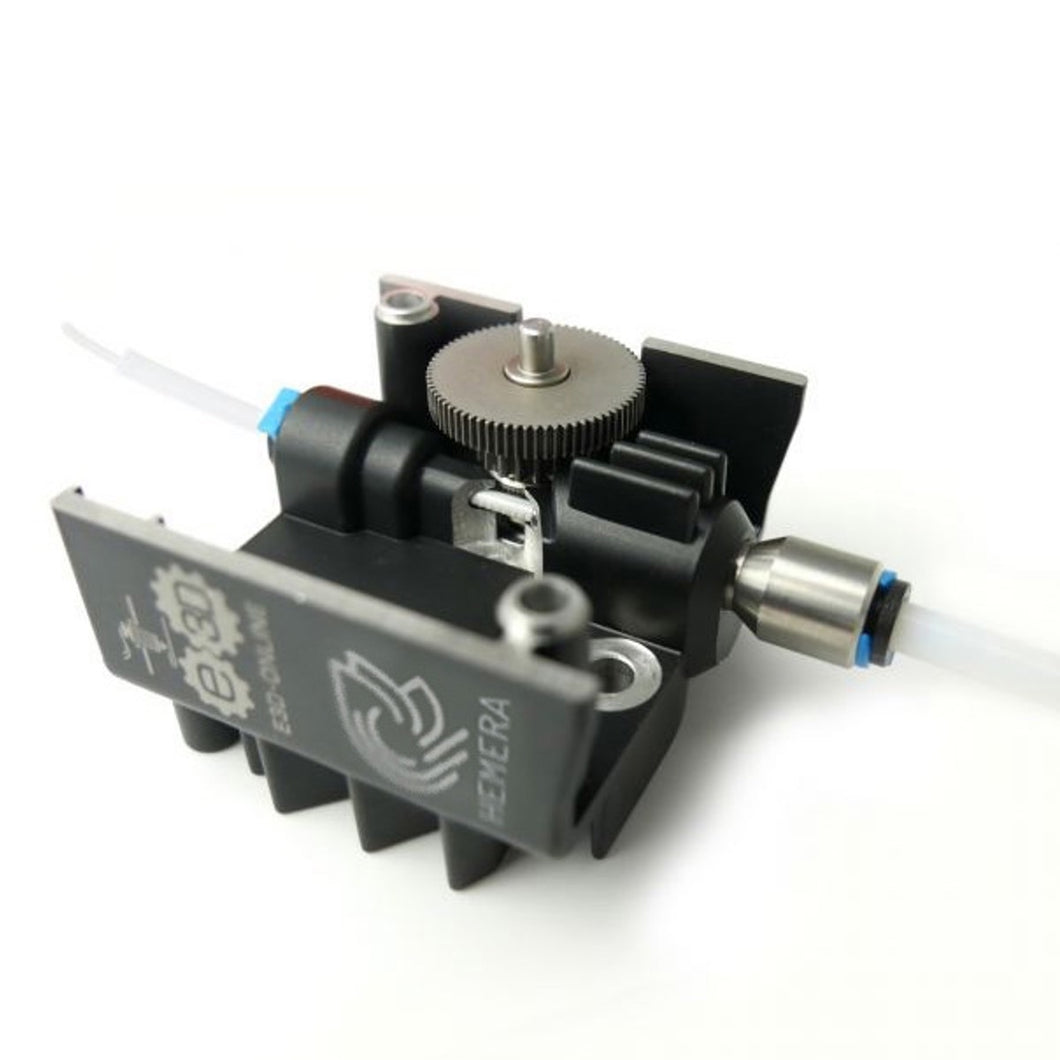

Sharp, individually machined hobb teeth ensure excellent filament grip strength, and round-bottomed profiles help to reduce any build-up of filament debris, for high-quality, consistent extrusion from first to final layer.Į3D quality. Hemera’s 3.32:1 dual drive gears produce pushing force of up to 120N on your filament from both sides, for accurate, controlled extrusion with no loss of torque. Air is circulated through the fins and then up and away from the 3D print, preventing any unintentional warping of the printed part. Hemera has a uniquely designed lightweight aluminium heatsink for highly effective cooling. (Disclaimer: abrasion-resistant Revo Nozzle required – ETA 2022) Hemera’s stainless steel hobb teeth are resistant to wear, so with the right combination of components, your Hemera can effortlessly 3D print advanced abrasive and composite materials, like carbon fibre-filled filaments, for serious industrial applications. Even with the softest flexibles, you can print without the underextrusion or filament binding you would get with a typical setup. Hemera is a combined extruder and HotEnd, so it has fewer transitions than most extrusion systems available. A tight filament path gives it excellent performance with hard-to-print materials, like flexibles. A Revo HeaterCore heats up in seconds. It’s much safer too – unlike other solutions on the market, a positive temperature coefficient (PTC) means the Revo HeaterCore can not melt at extreme temperatures: power reduces as it gets hotter, so hazards are reduced in the event of a thermal runaway. Revo Nozzles are a factory sealed nozzle and heatbreak in one, so they’re easy to fit and can’t leak material when in use. Change nozzles at room temperature using just your fingers. Therefore, E3D Hemera it is not compatible with other Nema 17 motors and you'll not be able to swap the motor with either a compact but powerful/ slimline motor or other 3rd party motors.Ready for Revo. *Please note* - whilst the custom motor is similar to a Nema 17, it isn’t a standard Nema 17. Hemera's heatsink design ensures airflow is diverted up and away from both the HotEnd and the heated bed, reducing the risk of warping and uneven stresses forming in the printed part.

But trust E3D - the performance is second to none and also has a significant impact on printing normal materials such as PLA or PETG. You won’t truly ‘get’ the impact of the optimized constraint that Hermes provides until you’ve printed flexibles with it.

Hemera constrains your filament like no other hotEnd/extruder combination. This is neat as it allows E3D to use the motor itself as part of the assembly and to add their own features for the user’s convenience, such as the mounting T-Slots. To achieve this, E3D has developed a custom motor, based on a NEMA17 frame, with their own faceplate designs. Hemera is a system of components designed to work seamlessly together as a single product. The round bottom of the profile strongly resists filament debris wedging into the drive gear and in almost all cases it’s self-cleaning as any debris simply falls off the teeth.Į3D set out to develop a compact extruder and HotEnd system with a reduced part-count. Individually CNC cutting each hobb allows for a round-bottomed root, with a tooth that curves upwards to a robust, sharp tip. Featuring dual drive gears, auto-loading compatibility, and fantastic grip strength providing a reliable extrusion system that minimizes slipping and grinding.Į3D Hemera is a dual-drive system with a hardened stainless steel drive train. (via Canada Post)Į3D Hemera (formerly known as Hermes) is a powerful next-generation extruder.

#Hemera e3d free

Free shipping in Canada for orders over $140 before tax.

0 kommentar(er)

0 kommentar(er)